Shell has launched Shell Bitumen CarbonSink, a new bio-component binder that locks carbon into asphalt and bitumen, turning roads into technical ‘carbon sinks’.

And as the asphalt is recyclable, most of the carbon will not re-enter the atmosphere even at the end of the road's life, the energy giant said.

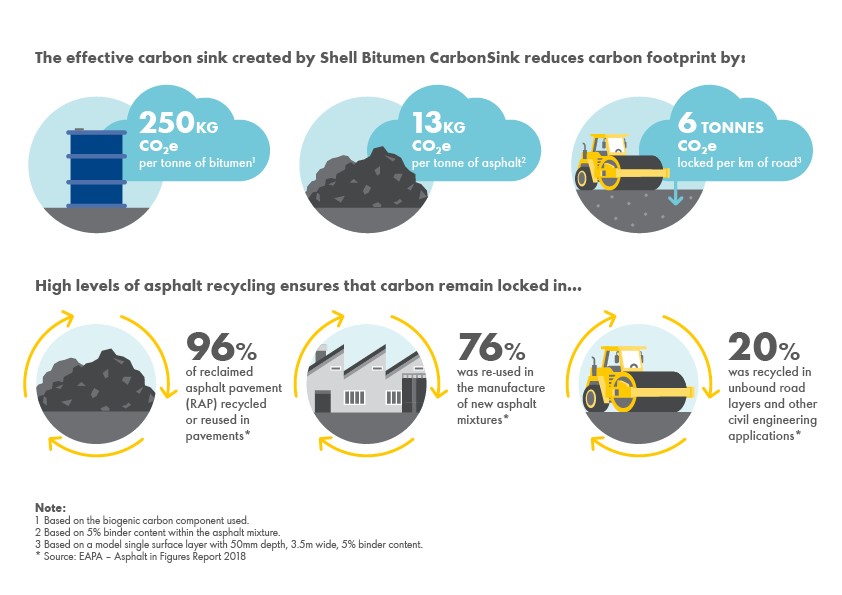

Shell said its Bitumen CarbonSink reduces the carbon footprint of one tonne of bitumen 'by up to 250kg of CO2 equivalent and the carbon footprint of one tonne of asphalt by up to 13kg of CO2 equivalent' - meaning 'up to six tonnes of CO2 equivalent can be locked in per kilometre of road'.

This is based on a model single surface layer with 50mm depth, 3.5, width, and 5% binder content.

'This solution is a great example of how innovation can help decarbonise construction and improve circularity at the same time,' said Raman Ojha, vice president, Shell Construction and Road.

'We want to be a partner for change within the construction sector, supporting our customers by providing them with decarbonisation solutions as we work towards confronting construction’s carbon challenge, together.'

The bitumen has already been deployed in the UK by Aggregate Industries for its SuperLow-Carbon asphalt and is being launched in multiple markets to be used at scale across the global road network.