The latest survey results from Highways Asks in partnership with IKO Road suggest that the sector has a long way to go when it comes to understanding whole-life costs in typical maintenance repairs and wider asset management strategies.

Following polling of senior managers and decision-makers in the highways sector, the latest Highways Asks survey found that ‘due to budget constraints’ almost two out of five (38.6%) clients and contractors still work ‘mainly on price’ rather than whole-life cost when it comes to choosing materials and techniques for maintenance and repairs.

The result is that many repairs made on the network do not appear to be the most durable and will need to be revisited again and again within a five-year period, potentially costing more cash in the long run and increasing carbon emissions.

Of the scores of respondents to the survey, 10% said spray injection patching could have to be revisited more than three times in five years and 40.9% said cold applied repairs could have to be repatched as many times in the same period.

Despite the fact that hot repairs with asphalt, mastic or bitumen-based material were found to be the most durable they were not always among the first choice of technique in certain areas of the network with a minority 41.9% stating they would be a top choice for bridge decks.

The majority of respondents (56.8%) said they applied an understanding of whole-life costs based on supplier credentials and in-house knowledge, but only a minority said they were able to develop a more exact understanding – such as using testing, trials or third party analysis – and record evidence of the whole-life cost of the materials used in repairs.

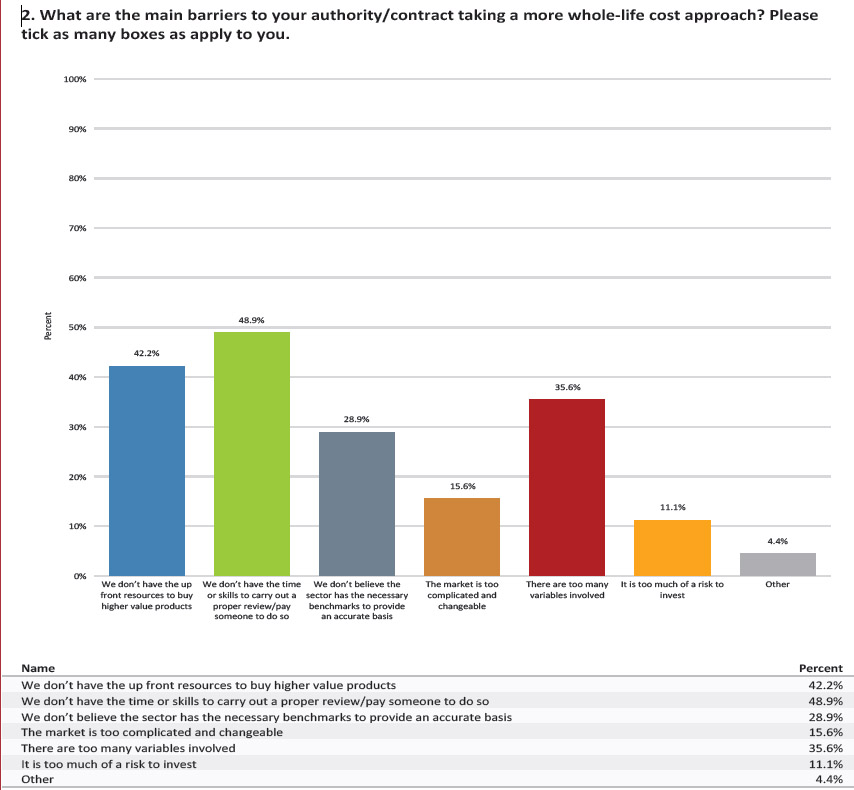

Among the main barriers to an authority or contractor developing a whole-life cost strategy for maintenance was a lack of up-front resources according to 42.2% of respondents, while 48.9% said they lacked the time or skills to carry out a proper review or the ability to pay a third party to do so.

Interestingly, close to a third of respondents (28.9%) said they did not believe the sector has the necessary benchmarks to provide an accurate basis for whole-life costing, and more than a third (35.6%) said there are too many variables involved.

One in nine (11.1%) considered it was ‘too much risk to invest’ in bringing down whole-life costs, and one in six (15.6%) said the market is too complicated and changeable.

‘PLEASE NOTE: The term thermal road repairs used in this article refers to a generic technique – more specifically called Infra-Red Thermal Repairs, not to any specific company or organisation with a similar or same name.

The survey also provided detailed insights into respondents’ experience of which materials and techniques were used where and how long they lasted.

Putting these factors together revealed that some of the most popular repairs often had the worst durability, with sites having to be revisited sometimes three or more times in five years.

In general, the trend confirmed that the longest-lasting repairs were used on the more strategic routes and enjoyed the most use in general. For instance, patching with hot asphalt, mastic or bitumen-based material was found to be most popular on A roads where 79.1% said it was the most likely repair technique used.

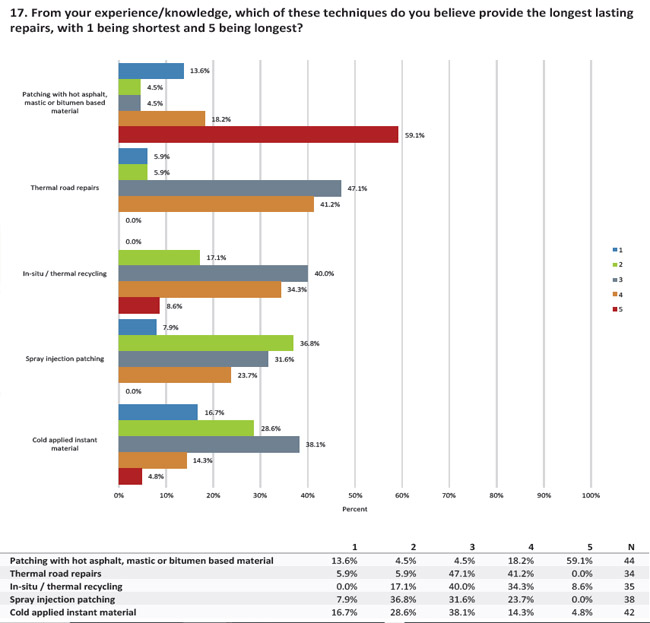

Around 56% said it was the most likely repair on the strategic road network (SRN). This was the highest percentage for the SRN of all the options, which included thermal road repairs, in-situ thermal recycling, spray injection patching and cold applied instant materials. Respondents were asked to rank these techniques from 1-5, with five being the most used and one being the least.

Only 4.8% said cold applied instant material was the longest-lasting repair and patching system. However more than a third said cold applied techniques were one of the most popular choices of technique on the SRN and a majority said it was one of the most popular on A roads.

In general, only 15.9% said cold applied material scored a five for most used technique on the network.

Spray injection patching was the most used or the second most used with more than 20% of respondents. This is despite the fact that 10% said these repairs would have to be revisited more than three times in a five-year period. A further 55% said the repair would have to be revisited at least twice or three times.

This is compared to ‘hot asphalt, mastic or bitumen based material’, which a majority of 59.1% said was the longest-lasting repair and only 9% said it would require revisiting more than twice. Roughly the same percentage said a thermal road repair would have to be revisited more than twice and 14.7% said thermal recycling in situ would need to be revisited more than twice.

Analysis

By Wayne Perrin, Sub Divisional Sales Manager – IKO Road

IKO Road is proud to support the latest Highways Asks survey, which has given fresh insight into repair techniques and some of the opportunities for efficiencies in this area.

The survey shows that in some cases councils could need to revisit a repair several times even in the space of a few years. That is a maintenance cycle that has to be broken if we are to work our way out of financial constraints.

To break this cycle, we need to understand how a suite of techniques and different materials can be targeted in different areas to produce the best results.

At the heart of the issue, lies the conundrum of whole-life cost; how we understand it and how we apply it. Unfortunately, it seems we still have some way to go on this, with a large section of the sector conceding that such calculations are not possible due to financial constraints. Of course, the Catch-22 here is that without a proper understanding of whole-life costs we can’t deliver maximum value for money.

It seems that many councils are treating repairs as an emergency, something that must be dealt with as quickly, not necessarily as efficiently, as possible. In fact, if a repair is done right first time, councils will get more done and have less reactive maintenance over the long-term. Ultimately, we can deliver more productivity if repairs are part of a wider, long-term strategy.

For instance, low-temperature materials have a place, especially given the high priority we must place on carbon reduction. However, if we don’t understand the whole-life cost of using these materials compared to more durable techniques, we cannot promise that we are genuinely delivering a cut in carbon.

Mastic asphalt should be top of the list when it comes to durable repairs, especially for key routes and strategic assets, where closing the road can be expensive and disruptive.

The benefits of mastic asphalt are that it contains a higher percentage of bitumen binder, so it is an easy-to-lay, flowable material and is voidless and therefore needs no compaction. Crucially, it is also waterproof. This means it is not subject to the typical wear and tear that come with the freeze and thaw cycles of water ingress - so punishing in highly trafficked roads. The material cost to fix a pothole or cracking would be on par with some of the cold-applied, bag products and would last much longer as this survey shows.

IKO Road is the specialist in this area and provides long-lasting mastic asphalt repair solutions across the UK. On busy routes and key assets, mastic asphalt provides quick and effective, right first time solutions that outlast alternatives.

We apply a risk-based approach to when and where we repair, so why not how we repair? In every action, whether it’s developing an asset management strategy or delivering a defect repair, we need to make the right long-term decision based on whole-life costs.

For more information visit: https://ikogroup.co.uk/highways-civils/